|

Size: 3122

Comment:

|

Size: 1008

Comment:

|

| Deletions are marked like this. | Additions are marked like this. |

| Line 1: | Line 1: |

| == Task list == [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=4792]] |

<<TableOfContents(3)>> |

| Line 4: | Line 3: |

| = Type-A Meeting on 2016/6/21 = 2016/6/21 13:00 - 14:00 by Skype |

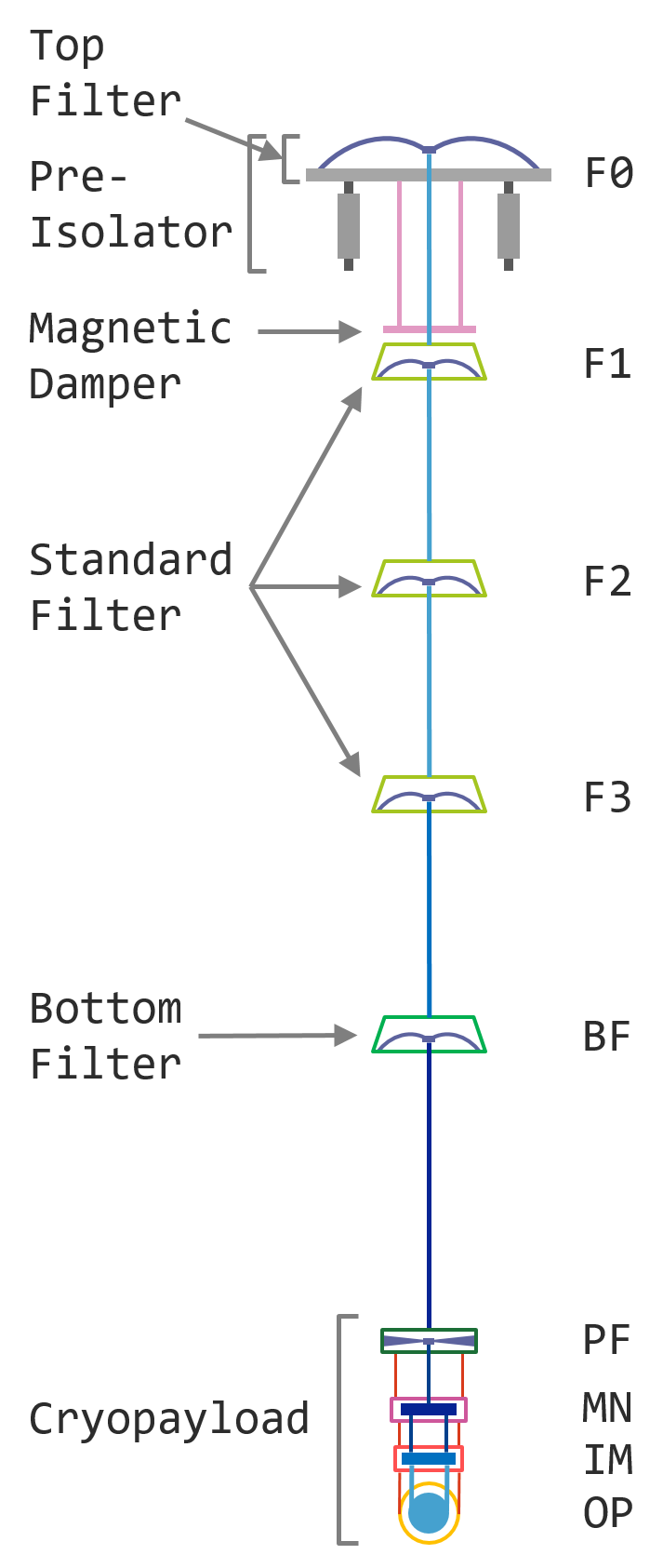

= Design = . [[TypeAdesign|{{attachment:figTypeAsasNamed1.png||width=25%,align="right"}}]] == Drawings == See also [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=4005|JGW-E1504005]]: VIS Document and Drawing Tree (Type-A) |

| Line 7: | Line 8: |

| Participants: Takahashi, Ishizaki, Sato | ==== Mechanical Stages ==== * Type-A SAS whole assy * [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=5634|Pre-Isolator]] * [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=5636|Top Filter]] * [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=5637|Inverted Pendulum]] * [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=5635|Standard Filter]] * Bottom Filter |

| Line 9: | Line 16: |

| === Minutes === 0-1 Assembly model (Ishizaki) * Made the test setup. 0-2 Simulation (Okutomi) * Deadline: The end of June 2-3 Setting of cross chamber (VAC) * Work: From 8th July, presence on 11th. 3-5 ACC preparation (Sato) * Make working space in the 20m lab on 27th June. 4-3 Standard filter (Hirata) * Assembly of FR and measurement: by August for 6 sets. 4-5 Procurement of magnets (Takahashi) * Size: 13mm, 72PSC for each 5-1 Manufacturing of blade (Takahashi) * Cutting: 6 blades by July + 6 blades by Sep. 5-6 Design of damper (Sato) * Device: The last one was too small, actually about 125mm. Design for vertical as well. 6-1 Design of EQ stop (Ishizaki) * Modeling: 3D model for the test setup was build. 6-3 Test of prototype * Frame lock: Delivered by 24th. * Other parts (rod, adjuster, bolts) will be ordered. 6-4 Design of release sensor (Sato) * Base: Making in ATC. * Plate additional machining: Ordered. * Circuit: LED will be tested. 8-1 Design of dummy payload (Okutomi, Ishizaki) * Cartoon: Okutomi should send to Ishizaki soon! * Mirror holder: Refer the mirror box for PR. 9-1 Establishment of procedure (Takahashi, Okutomi) * Test plan: Check FR for 2 BFs. 9-3 Cable assembly * Number of cables: Thermocouples are added. Ask Tomaru total number. |

|

| Line 43: | Line 17: |

| Next meeting: 2016/6/28 13:00 | ----- = Schedule = [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=4792|Task list]] |

| Line 45: | Line 21: |

| = Type-A Meeting on 2016/6/14 = 2016/6/14 13:00 - 15:00 @ Room 210 |

= Meeting = |

| Line 48: | Line 23: |

| Participants: Takahashi, Ishizaki, Sato, Okutomi === Minutes === 0-1 Assembly model (Ishizaki) * Step: From EQ stop, next with chamber. 0-2 Simulation (Okutomi) * Problem: Conversion to Simulink was ok. The structure of control has a problem in Matlab. Reconstructing now. 3-5 ACC preparation (Sato) * Space: Make working space in the 20m lab. 5-1 Manufacturing of blade (Takahashi) * Design: 5 blades are used for 200kg load. 5-6 Design of damper (Sato) * Device: Asking design of LVDT-Act. to VIRGO. The device is located at the center of mass. 6-1 Design of EQ stop (Ishizaki) * Structure analysis: Two cases were calculated. Share stress was 1/6 of limit, and principal stress was 1/7 of limit respectively in the maximum case. * Modeling: Making with consideration of procedure and tools. * Frame lock: Maximum stress was 160MPa with thickness of 30mm (limit 180MPa). 6-4 Design of release sensor (Sato) * Position: Inner side of the stage. Need to addtional machining to the EQ stop plate. * Electronics: Circuit is simple in the test (handmade). 8-1 Design of dummy payload (Okutomi, Ishizaki) * Condition: 25cm mirror, alignment by moving mass. Make a cartoon. * Actuation: Length control is necessary? Check PZT actuator. 9-1 Establishment of procedure (Takahashi, Okutomi) * Test plan: Prepare for 2 sets of release sensors. Check FR for 2 BFs. Next meeting: 2016/6/21 13:00 |

* Type-A team meeting [[http://gwwiki.icrr.u-tokyo.ac.jp/JGWwiki/KAGRA/Subgroups/VIS/TypeA/Meeting|Minutes]] |

Design

Drawings

See also JGW-E1504005: VIS Document and Drawing Tree (Type-A)

Mechanical Stages

- Type-A SAS whole assy

- Bottom Filter

Schedule

Meeting

Type-A team meeting Minutes