|

Size: 1645

Comment:

|

Size: 874

Comment:

|

| Deletions are marked like this. | Additions are marked like this. |

| Line 1: | Line 1: |

| == Task list == [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=4792]] |

<<TableOfContents(3)>> |

| Line 4: | Line 3: |

| = Minutes of the Type-A Meeting on 2016/6/14 = 2016/6/14 13:00 - 15:00 @ Room 210 |

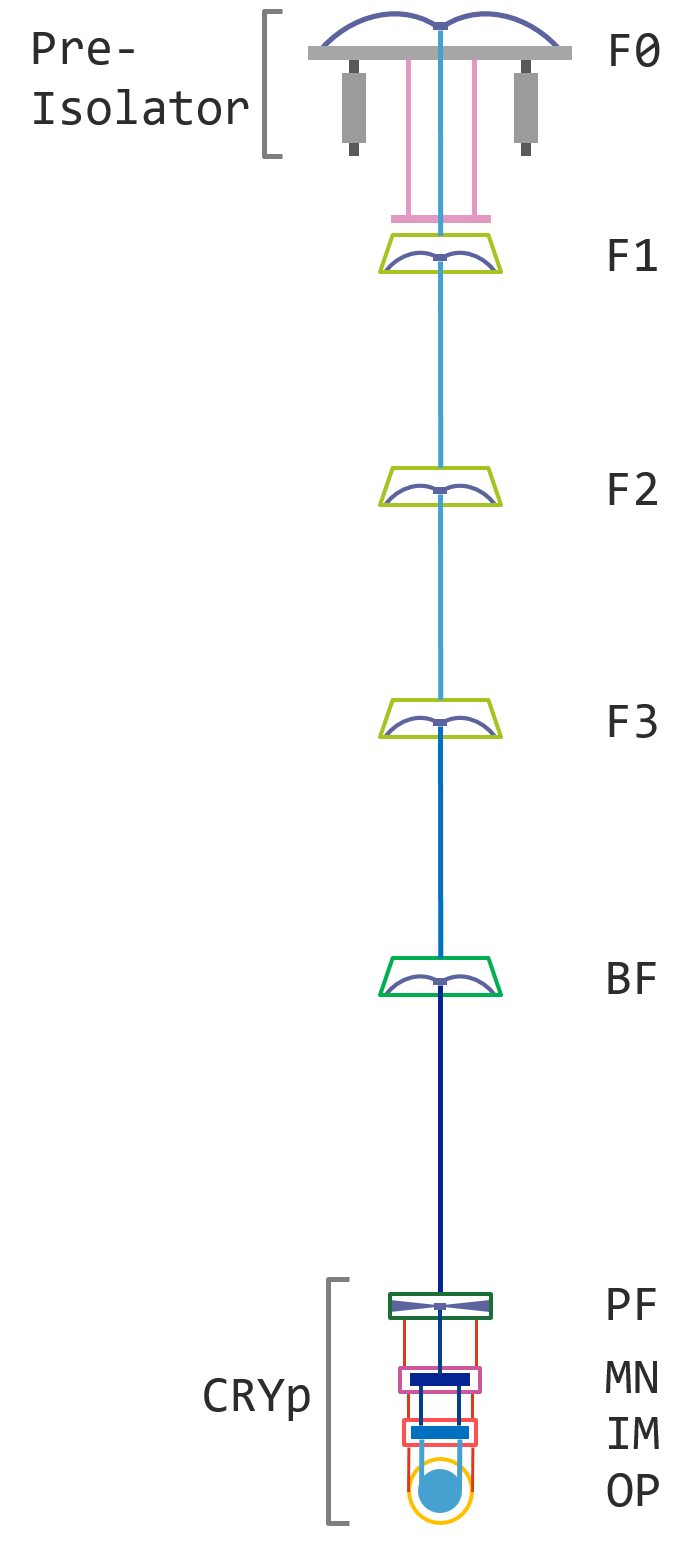

= Design = . [[TypeAdesign|{{attachment:figTypeAsasNamed.png||width=25%,align="right"}}]] == Mechanical Components == * Pre-Isolator (PI) * Inverted pendulum (IP) * Top filter (TF) * Magnetic damper (MD) * Standard filter (SF) * Bottom filter (BF) * Cryopayload (CRYp) * Platform (PF) * Marionette (MN) * Marionette recoil mass (MNR) * Intermediate mass (IM) * Intermediate recoil mass (IRM) * Optics (OP, test mass, TM) * Recoil mass (RM) |

| Line 7: | Line 21: |

| Participants: Takahashi, Ishizaki, Sato, Okutomi | == Drawings == * [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=5633|Pre-Isolator]] |

| Line 9: | Line 24: |

| === Minutes === 0-1 Assembly model (Ishizaki) * Step: From EQ stop, next with chamber. 0-2 Simulation (Okutomi) * Problem: Conversion to Simulink was ok. The structure of control has a problem in Matlab. Reconstructing now. 3-5 ACC preparation (Sato) * Space: Make working space in the 20m lab. 5-1 Manufacturing of blade (Takahashi) * Design: 5 blades are used for 200kg load. 5-6 Design of damper (Sato) * Device: Asking design of LVDT-Act. to VIRGO. The device is located at the center of mass. 6-1 Design of EQ stop (Ishizaki) * Structure analysis: Two cases were calculated. Share stress was 1/6 of limit, and principal stress was 1/7 of limit respectively in the maximum case. * Modeling: Making with consideration of procedure and tools. * Frame lock: Maximum stress was 160MPa with thickness of 30mm (limit 180MPa). 6-4 Design of release sensor (Sato) * Position: Inner side of the stage. Need to addtional machining to the EQ stop plate. * Electronics: Circuit is simple in the test (handmade). 8-1 Design of dummy payload (Okutomi, Ishizaki) * Condition: 25cm mirror, alignment by moving mass. Make a cartoon. * Actuation: Length control is necessary? Check PZT actuator. 9-1 Establishment of procedure (Takahashi, Okutomi) * Test plan: Prepare for 2 sets of release sensors. Check FR for 2 BFs. |

|

| Line 33: | Line 25: |

| === Next meeting === 2016/6/21 13:00 |

----- = Schedule = [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=4792|Task list]] = Meeting = * Type-A team meeting [[http://gwwiki.icrr.u-tokyo.ac.jp/JGWwiki/KAGRA/Subgroups/VIS/TypeA/Meeting|Minutes]] |

Contents

Design

Mechanical Components

- Pre-Isolator (PI)

- Inverted pendulum (IP)

- Top filter (TF)

- Magnetic damper (MD)

- Standard filter (SF)

- Bottom filter (BF)

- Cryopayload (CRYp)

- Platform (PF)

- Marionette (MN)

- Marionette recoil mass (MNR)

- Intermediate mass (IM)

- Intermediate recoil mass (IRM)

- Optics (OP, test mass, TM)

- Recoil mass (RM)

Drawings

Schedule

Meeting

Type-A team meeting Minutes