|

Size: 579

Comment:

|

Size: 1212

Comment:

|

| Deletions are marked like this. | Additions are marked like this. |

| Line 4: | Line 4: |

| === ETM === Each iKAGRA ETM suspension has 4 coils and 4 pico-motors (pitch:1-6, yaw:2-7, z:3-8, y:4-9). If you find a problem about coil-magnet actuator, please check 2 things. 1. Coil drivers in particular for Y-end had a loose connection with power line (-18V, -15V). Please check the LED on coil driver. If the LED is out, try to fasten the power line. 2. Sometimes watchdog? system stop the output current from the coil driver in order to protect mechanical system. |

|

| Line 5: | Line 18: |

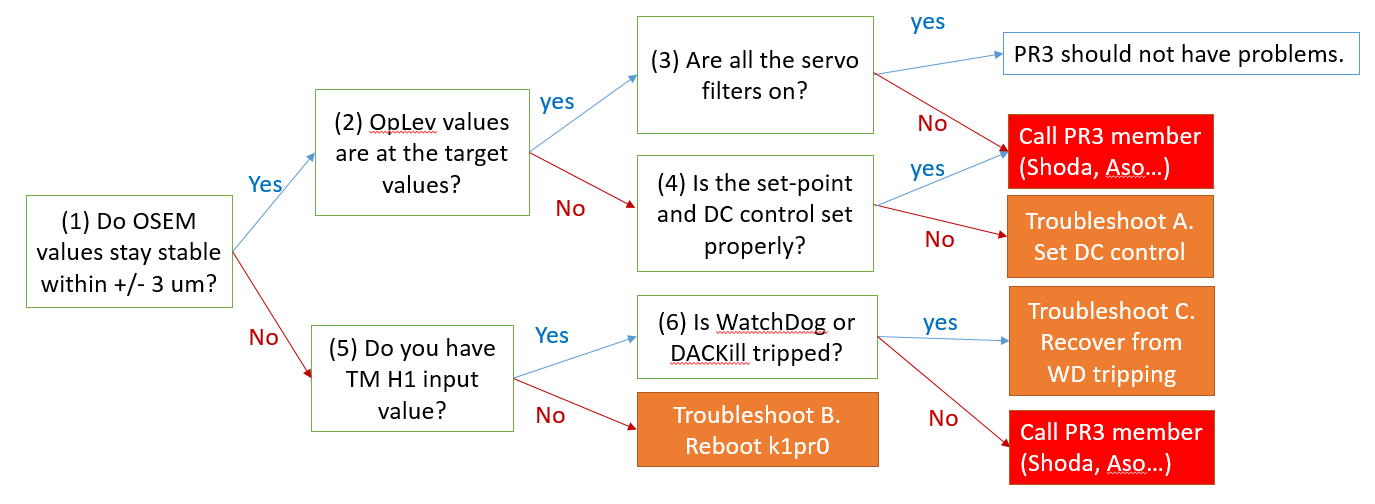

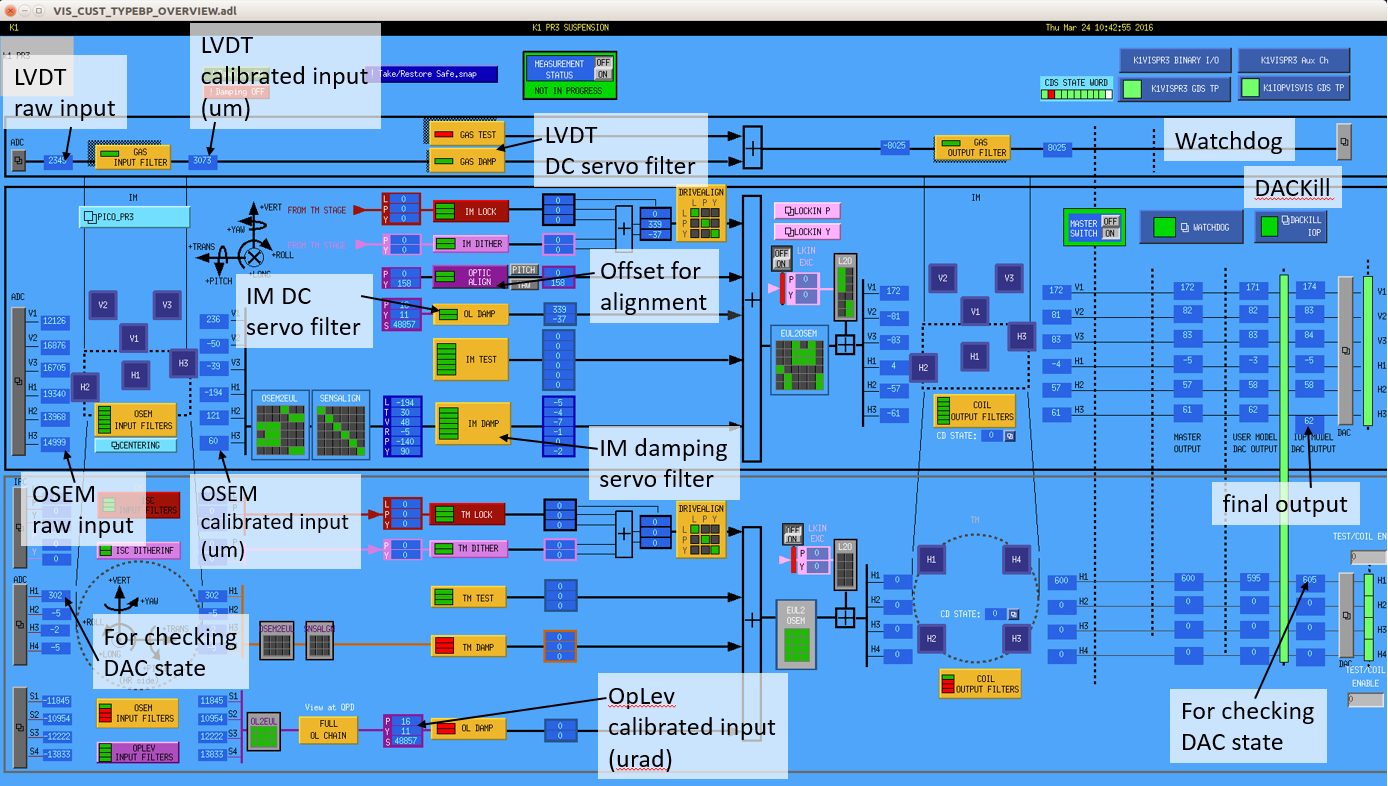

| Check the PR3 status according to the flowchart below. [[attachment:TroubleshootFlowchart.png|{{attachment:TroubleshootFlowchart.png|text describing image|width=800}}]] ==== Details of the check points ==== [[attachment:CheckPoint1-3.png|{{attachment:PR3overview.png|text describing image|width=800}}]] [[attachment:CheckPoint5-6.png|{{attachment:PR3overview.png|text describing image|width=800}}]] 1. Check point (1): Do OSEM values stay stable within +/- 3 um? The |

|

| Line 7: | Line 30: |

| === ETM === Each iKAGRA ETM suspension has 4 coils and 4 pico-motors connected. If the coil-magnet actuator seems to have a problem, please check 2 things. 1. Coil drivers in particular for Y-end had a loose connection with power line (-18V, -15V). Please check the LED on coil driver. If the LED is out, try to fasten the power line. 2. Sometimes watchdog? system stop the output current from the coil driver in order to protect mechanical system. |

==== Appendix ==== [[attachment:PR3overview.png|{{attachment:PR3overview.png|text describing image|width=800}}]] |

Mode Cleaner Suspensions

Each MC suspension has 4 coils and 2 pico-motors (pitch, yaw).

ETM

Each iKAGRA ETM suspension has 4 coils and 4 pico-motors (pitch:1-6, yaw:2-7, z:3-8, y:4-9).

If you find a problem about coil-magnet actuator, please check 2 things.

1. Coil drivers in particular for Y-end had a loose connection with power line (-18V, -15V).

Please check the LED on coil driver. If the LED is out, try to fasten the power line.

2. Sometimes watchdog? system stop the output current from the coil driver in order to protect mechanical system.

PR3

Check the PR3 status according to the flowchart below.

Details of the check points

- Check point (1): Do OSEM values stay stable within +/- 3 um?

- The