|

Size: 17393

Comment:

|

← Revision 170 as of 2021-11-02 17:29:27 ⇥

Size: 7940

Comment:

|

| Deletions are marked like this. | Additions are marked like this. |

| Line 1: | Line 1: |

| == Task list == [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=4792]] |

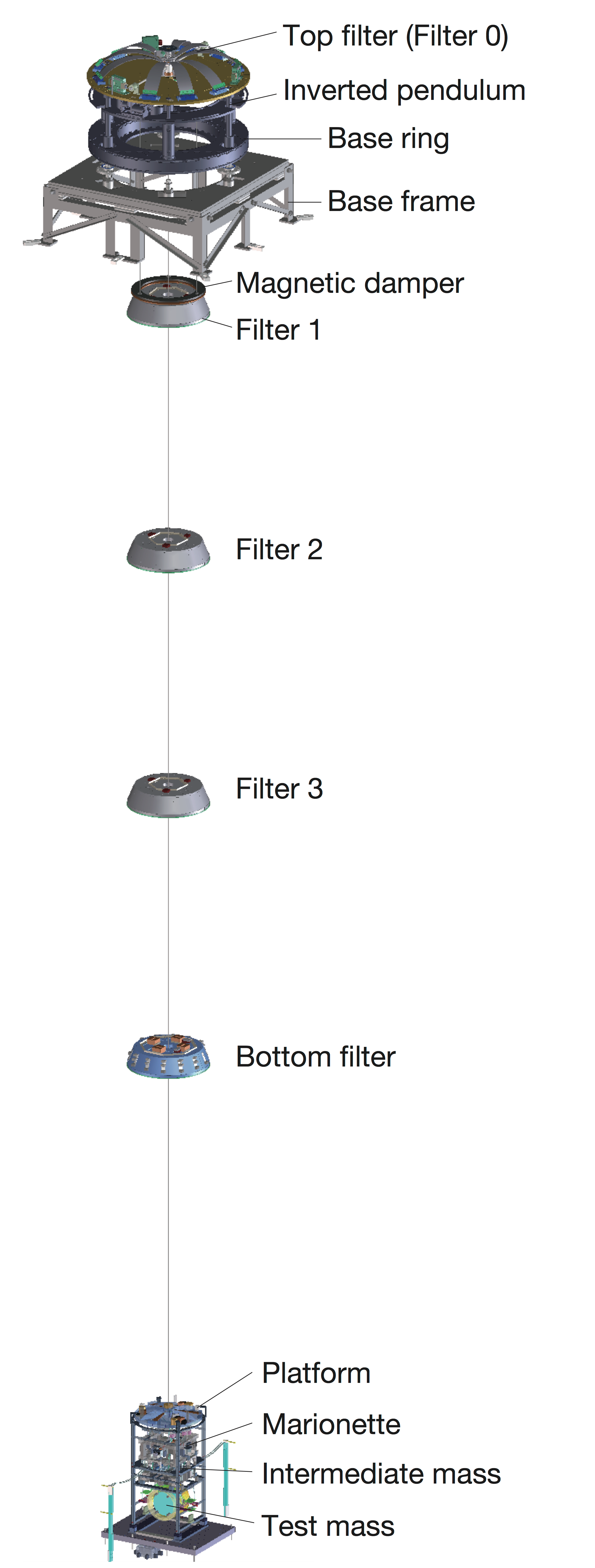

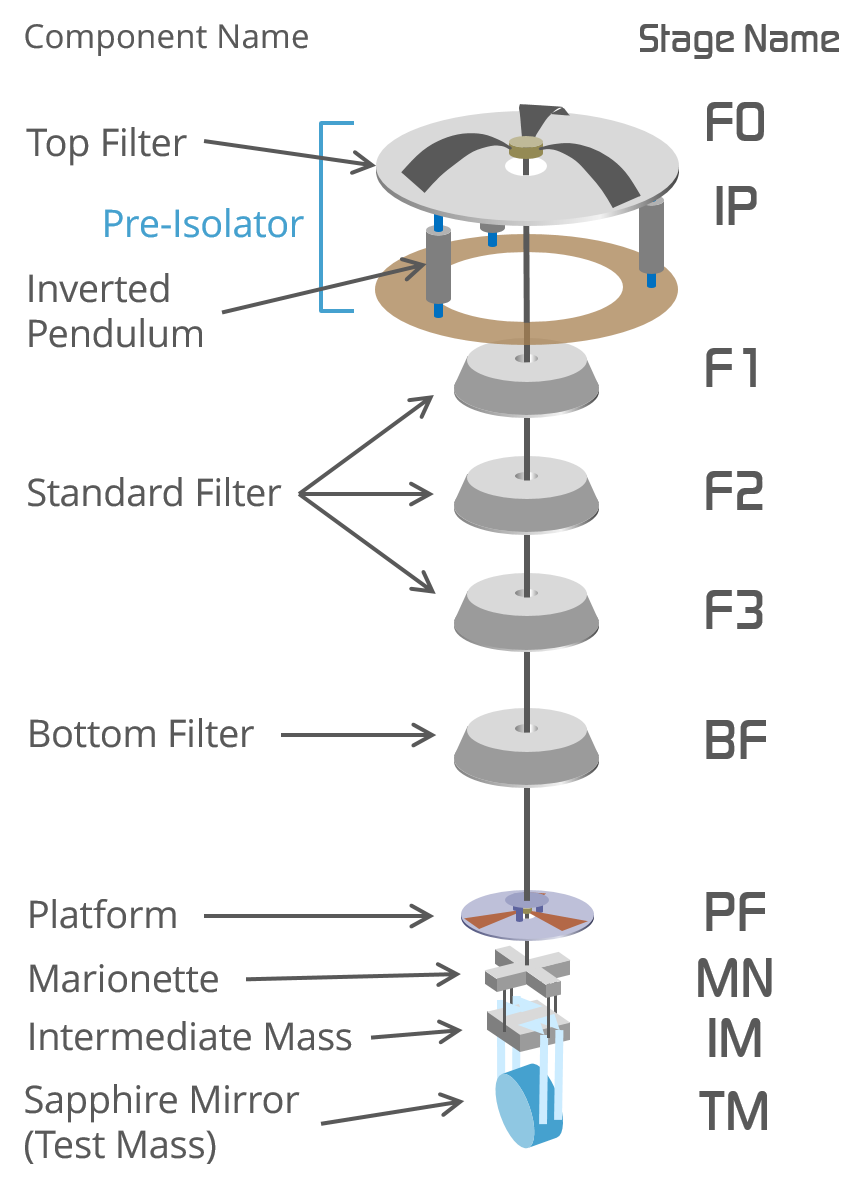

Information of the Type-A Seismic Attenuation System (SAS). This page wants information about not only room-temperature parts but also cryogenic vibration isolation system. |

| Line 4: | Line 4: |

| = Type-A Meeting on 2016/8/23 = 2016/8/23 13:00 - 14:30 @Large meeting room |

== Status == |

| Line 7: | Line 6: |

| Participants: Takahashi, Sato, Okutomi | * [[http://gwwiki.icrr.u-tokyo.ac.jp/JGWwiki/KAGRA/Subgroups/VIS/TypeA/WorkingLog|Site work log]] * [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=4792|Schedule (Task list)]] |

| Line 9: | Line 9: |

| === Minutes === 0-2 Simulation (Okutomi) * Calculating requirement for actuators and sensors. * Estimated the case using F7 LVDT, and the case using actual LVDT. * Summarized within today, and present in the f2f meeting. 2-1 Setting of top chamber (VAC) * Leak test should be performed in December, 2016. 3-2 Assembly of TF+IP (Sato) * Takahashi had a meeting on the place with Flaminio and Aso. * The place has not decided yet. Next meeting will be held on 25th. 3-5 ACC preparation (Sato) * Measured 6 sets were transported to Kamioka. * Calibration is planed at the site from 5th in September. 4-4 Transportation of SF (Hirata) * 6 sets were transported to Kamioka on 17th. 5-6 Design of damper (Sato) * Structure analysis was applied to the model. * Bracket of primary coil: 102Hz, bracket of secondary coil: 124Hz, including ring (t=20mm): 100Hz * The shape of adjustment hole will be changed from long circle to large circle. 5-8 Test of LVDT (Okutomi) * Designed adapter for primary coil. * Considering set up for actuator. * Coil bobbins of prototype were delivered on 19th. * Amplitude of oscillator should be larger (now 1V). 6-2 Procurement EQ stop (Takahashi) * The bidding was announced on 17th. Two companies had contact. 6-3 Test of prototype (Ishizaki) * Suspension test using maraging wires was performed on 18th. 6-6 Circuit for release sensor (Sato) * This item should be added. 9-6~9 Installation (Ishizaki) * Protection net, hoist tool, foot hold, handling tool were added as new item. |

* [[http://gwwiki.icrr.u-tokyo.ac.jp/JGWwiki/KAGRA/Subgroups/VIS/TypeA/ETMX|ETMX]] * [[http://gwwiki.icrr.u-tokyo.ac.jp/JGWwiki/KAGRA/Subgroups/VIS/TypeA/ETMY|ETMY]] * [[http://gwwiki.icrr.u-tokyo.ac.jp/JGWwiki/KAGRA/Subgroups/VIS/TypeA/ITMX|ITMX]] * [[http://gwwiki.icrr.u-tokyo.ac.jp/JGWwiki/KAGRA/Subgroups/VIS/TypeA/ITMY|ITMY]] |

| Line 42: | Line 14: |

| Next meeting: 2016/8/30 13:00 | ------ <<TableOfContents(3)>> |

| Line 44: | Line 17: |

| = Type-A Review on 2016/8/10 = [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=5516]] |

[[TypeAoverview|{{attachment:TypeAoverview.png||width=33%,align="right"}}]] [[TypeAdesign|{{attachment:figTypeAsasNamed3.png||width=33%,align="right"}}]] |

| Line 47: | Line 20: |

| = Type-A Meeting on 2016/8/9 = 2016/8/9 13:00 - 14:00 @Room210 |

== Drawings == |

| Line 50: | Line 22: |

| Participants: Takahashi, Ishizaki, Sato, Okutomi | * Type-A SAS whole assy * Vacuum chamber * [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=5794|Vertical]] (IXV, EXV, IYV, EYV) * Cryostat |

| Line 52: | Line 27: |

| === Minutes === 0-1 Assy. (Ishizaki) * Made the model of EQ stop. 0-2 Simulation (Okutomi) * Calculated coupling to the yaw mode assuming asymmetry of 1mm and 3mm. The result was linear. * Updating the calculation (Next by 8/10). 3-5 ACC preparation (Sato) * Additional 3 sets have not been extracted yet. 3-6 Procurement of counter weight * Delay. 4-2,3 Standard filter (Hirata) * The 6th set will be finished on 10th. 5-6 Design of damper (Sato) * Design of frame and jigs was progressed. * We consulted with a company on procurement. 5-8 Test of LVDT (Okutomi) * Measured responce of LVDT sample. The signal was linear in 20mm range. * Found phase noise at the level of 10^-6m/rtHz. * Bracket for prototype is necessary. 6-1 Design of EQ stop (Ishizaki) * Made 2D drawings for the bidding. * Tolerance and surface accuracy should be indicated. * The tolerance for the rods with the same length must be less than 0.2mm. * The specification document and drawings should be sent by the 12th. 6-4 Design of release sensor (Sato) * Height of base was 56mm. Changed to 50mm. 8-1 Design of dummy payload (Okutomi, Ishizaki) * The length of Hook was reduced. 9-1 Installation procedure (Takahashi) * The document will be revised by the review. 9-3 Cable assembly (Sato) * Total 20 system. * 7 interfaces are necessary. |

=== Tower === * [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=5460|Earthquake stop - Security frame]] * [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=6918|Pre-Isolator]] * [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=5636|Top Filter (TF)]] * [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=5637|Inverted Pendulum (IP)]] * [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=5638|F0 LVDT-actuator unit]] * [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=5639|Blade spring for static position adjustment]] * Magnetic Damper (MD) * [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=5635|Standard Filter (SF)]] * Bottom Filter (BF) * [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=5656|BF LVDT and Attachments]] * [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=2555|Fishing rod]] * [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=5743|Maraging wire]] * [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=5461|Dummy Payload]] * [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=5462|Hoist's tools]] |

| Line 86: | Line 43: |

| Next meeting: 2016/8/16 13:00 | === Cryogenic Payload === * Cryo-Payload assy * Platform (PF) * Marionette (MT) * Marionette Recoil Mass * Intermediate Mass (IM) * Intermediate Recoil Mass * Test Mass (TM) - Sapphire Mirror * Recoil Mass * Heat link * Heat link suspension |

| Line 88: | Line 55: |

| = Type-A Meeting on 2016/8/1 = 2016/8/1 13:00 - 16:00 @Room210 |

----- == Documents == === Reports === * [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=5196|Requirements for Type-A SAS]] |

| Line 91: | Line 60: |

| Participants: Takahashi, Ishizaki, Sato, Okutomi | === Installation Procedure === * [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=410|Initial concept]] * [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=5500|Installation procedure of Type-A system]] * [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=9838|Installation direction of Bottom Filter]] * [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=10522|TF Yaw drive mechanism Initial adjustment]] === Measurement and Analysis === * Type-A Control Simulation * [[https://docs.google.com/spreadsheets/d/1QlaeJ4hME5J6iZWzPmfPFsq5aKwTP3a-1Rd9sqKIExM/edit?usp=sharing|Parameters for simulation]] * Shared with Google spread sheet (Browsing and commenting are permitted. Please contact to Okutomi for editing permission.) * Under checking the parameters to be more realistic based on measurements and drawings |

| Line 93: | Line 71: |

| === Minutes === 0-1 Assy. (Ishizaki) * Made the model of EQ stop and pre-isolator. * Each filter is placed at the side stopper. * The IP is put on the top plate directly at present, but a gap is necessary. * Take account of stretch of the wires. 0-2 Simulation (Okutomi) * Introduction of coupling to the yaw mode was wrong in the last calculation. * Updating the calculation. 1-1 Clean booth (FCL) * The lighting is made by the LED inside the booth. 3-2 Assembly of TF+IP (Sato) * The assembly work will be started on 30th August at the KAGRA site. 3-5 ACC preparation (Sato) * Additional 3 sets have not been extracted yet. 4-2,3 Standard filter (Hirata) * The 5th set was finished. 5-1 Manufacturing of blade (Takahashi) * The thermal process for the blades was finished. 5-6 Design of damper (Sato) * The plate for damper is independent of EQ stop frame. * Each LVDT has position adjustment. 5-8 Test of LVDT (Okutomi) * Set the test bench for LVDT sample at ATC lab. * Making 2-pin lemo cables. * A summer student will join to the test. 6-1 Design of EQ stop (Ishizaki) * Made 2D drawings for the bidding. * The date for the announce of bidding is the 17th August. * The specification document and drawings should be fixed by the 10th. 6-3 Test of prototype (Ishizaki) * Tested connection and lift down of the EQ stop prototype on 27th July. 6-4 Design of release sensor (Sato) * Set at 5mm under of each filter. * The shape of jigs will be modified with thick base. 8-1 Design of dummy payload (Okutomi, Ishizaki) * The bottom should be a breadboard with 50mm interval. 9-1 Installation procedure (Takahashi) * The first draft was shown and discussed. * The height setting for each filter is important. |

* [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=5105|[2016.08.15] Measurements of Standard Filter]] . Data of weight, optimal load, GAS resonant frequency, keystone height . Combination of the standard filters for Type-A with ID * X end: 3-2(F1), 2-2(F2), 1-4(F3) * Y end: 3-3(F1), 2-1(F2), 1-3(F3) |

| Line 134: | Line 77: |

| Next meeting: 2016/8/9 13:00 | * [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=5707|[2016.09.30] Measurements of BF LVDT Prototype]] * [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=5099|[2016.11.15] Bottom filter optimal wight re-measurement]] |

| Line 136: | Line 80: |

| = Type-A Meeting on 2016/7/26 = 2016/7/26 13:00 - 14:20 @Room210 |

----- == Electronics == |

| Line 139: | Line 83: |

| Participants: Takahashi, Ishizaki, Sato, Okutomi | * General * [[http://gwwiki.icrr.u-tokyo.ac.jp/JGWwiki/KAGRA/Subgroups/VIS/TypeA/DGSrack|DGS rack layout]] * [[http://gwwiki.icrr.u-tokyo.ac.jp/JGWwiki/KAGRA/Subgroups/VIS/TypeA/DGSchannel|ADC/DAC channel assignment]] * [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=5193|List of drivers for VIS]] * [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=817|Lecture of Standalone Digital system for VIS]] * [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=1737|ADC board]] * [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=1736|DAC board]] * Quick information * ADC accepts +/- 10 V differential = * LVDT * [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=2826|LVDT Driver]] * [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=2117|LVDT-coil distributor]] * LVDT-coil combiner * Accelerometer * ACC driver * Geophone * [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=1466|Preamp circuit]] * Coil-magnet actuator * [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=3502|High power coil driver]] * [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=3506|Low power coil driver]] * Optical lever * QPD board * Stepper motor * Stepper motor driver * Picomotor * Picomotor driver * Cabling * [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=7587|In-Vacuum cables (hand made)]] * Type-A suspension cabling O4 [[https://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=13378|<EX>]], [[https://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=13375|<EY>]], [[https://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=13404|<IX>]], [[https://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=13406|<IY>]] * [[https://www.dropbox.com/sh/hkpunq1fjp7nduc/AAAzCL7GbeWAjGiGW8j3zDX2a?dl=0|Photos at installation (link to KAGRA dropbox)]] * [[http://gwwiki.icrr.u-tokyo.ac.jp/JGWwiki/KAGRA/Subgroups/VIS/TypeA/Feedthough|Cable assignment at feedthough and filter side]] * [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=9839|Result of continuity check and resistance measurement at installation]] * [[https://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=11625|Pin assignment at feedthrough]] |

| Line 141: | Line 117: |

| === Minutes === 0-1 Assy. (Ishizaki) * The modeling of EQ stop was almost finished. * The model of chamber will be added to it. 0-2 Simulation (Okutomi) * Calculated the effect due to actuation point for BF. * Noise will be induced to the actuators taking account of measured LVDT. 1-1 Clean booth (FCL) * Design of suspended booth was shown. * The lighting is OK? 3-2 Assembly of TF+IP (Sato) * Decision on the working place is under negosiation. * From August 30. 3-5 ACC preparation (Sato) * Additional 3 sets will be taken by the end of July. 4-2,3 Standard filter (Hirata) * The 4th set is on going. 4-5 Procurement of damper magnet * Ordered. 5-1 Manufacturing of blade (Takahashi) * Blades are in the thermal process. 5-6 Design of damper (Sato) * Made drawings for LVDT prototype. * Make drawings for EQ stop side. 5-8 Test of LVDT (Okutomi) * Set the sample from VIRGO in the 20m lab. * Making connector cables. * Micrometer stage and some jigs are necessary. 6-1 Design of EQ stop (Ishizaki) * Made 3D model and 2D drawings. * Bottom support for the dummy payload is necessary. * Gap of the side stopper should be 10mm. * Adjustment of top ring position is not necessary. 6-3 Test of prototype (Ishizaki) * Outer diameter of the plate was reduced on 20th. 6-4 Design of release sensor (Sato) * The shape of jigs was modified with 30mm in height. * Gutter for cables is necessary. 8-1 Design of dummy payload (Okutomi, Ishizaki) * The height was reduced. 9-3 Cable assembly (Sato) * This task was postponed. 9-6 Protection net (Okutomi) * The smallest bolt size was M3. |

|

| Line 186: | Line 118: |

| Next meeting: 2016/8/1 13:00 | |

| Line 188: | Line 119: |

| = Type-A Meeting on 2016/7/19 = 2016/7/19 13:00 - 15:00 @Room210 |

----- == Members of Type-A Team == . Ryutaro TAKAHASHI (Leader) . Naohisa SATO . Lucia TROZZO . Yoshinori FUJII . Koki OKUTOMI . Hideharu ISHIZAKI |

| Line 191: | Line 128: |

| Participants: Takahashi, Ishizaki, Sato, Okutomi(Skype) | == Meeting == * NAOJ VIS Meeting [[http://gwwiki.icrr.u-tokyo.ac.jp/JGWwiki/KAGRA/Subgroups/VIS/MeetingNAOJ|Minutes]] * Type-A team meeting [[http://gwwiki.icrr.u-tokyo.ac.jp/JGWwiki/KAGRA/Subgroups/VIS/TypeA/Meeting|Minutes]] |

| Line 193: | Line 132: |

| === Minutes === 0-1 Assy, (Ishizaki) * The plate for BF is in the center of cross tube. 0-2 Simulation (Okutomi) * Calculate the effect due to actuation point for BF. 2-3 Setting of cross chamber (VAC) * Remained horizontal deviation between the top flange on the cryostat and the top chamber was 1-4mm. 3-2 Assembly of TF+IP (Sato) * The assembly work was rescheduled. From the end of August at the site. 3-5 ACC preparation (Sato) * Additional 3 sets will be taken from NM1 in TAMA by the end of July. * ACCs will be calibrated at the site. 4-2,3 Standard filter (Hirata) * 3 sets were finished. 5-1 Manufacturing of blade (Takahashi) * Blades are in the thermal process. 5-6 Design of damper (Sato) * Samples of LVDT have been delivered from VIRGO. * Design work is going. 6-1 Design of EQ stop (Ishizaki) * Made 3D model and some 2D drawings. * Guide for lift down is necessary. 6-3 Test of prototype (Ishizaki) * Outer diameter of the plate will be reduced on 20th. 6-4 Design of release sensor (Sato) * Length of the present lead cable is too short. Longer ones will be prepared for actual setup. 7-2 Long Maraging rod (Takahashi) * Rod for cryo-payload should be lift down at beginning and fixed on the protection net temporally. 8-1 Design of dummy payload (Okutomi, Ishizaki) * Made drawings. The present design is too tall. * Confirm the height of mounted items. 9-6 Protection net (Okutomi) * Check the small bolts size to decide the mesh of net. |

== See also == * [[http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=4005|JGW-E1504005]]: VIS Document and Drawing Tree (Type-A) * [[https://www.dropbox.com/home|KAGRA Dropbox]] > [[https://www.dropbox.com/home/Subsystems|Subsystems]] > [[https://www.dropbox.com/home/Subsystems/VIS|VIS]] > [[https://www.dropbox.com/home/Subsystems/VIS/TypeA|TypeA]] * [[http://gwwiki.icrr.u-tokyo.ac.jp/JGWwiki/KAGRA/Subgroups/CRY|KAGRA/Subgroups/CRY]] |

| Line 227: | Line 137: |

| Next meeting: 2016/7/26 13:00 = Type-A Meeting on 2016/7/12 = 2016/7/12 11:00 - 12:30 @Kashiwa Participants: Takahashi, Ishizaki(Skype), Sato, Okutomi === Minutes === 0-2 Simulation (Okutomi) * The frequency shift was due to damping model. * Setting for GAS filters was corrected. * Going BF damping simulation by manual tuning. * Result will be reported by the VIS meeting. 2-3 Setting of cross chamber (VAC) * Horizontal position of the top flange on the cryostat was different from the center of the top chamber by 25mm along beam axis. 3-2 Assembly of TF+IP (Sato) * The place should be in the center room of KAGRA considering DGS setup. 3-5 ACC preparation (Sato) * 6 sets of ACC were measured. * Additional 3 sets will be taken from NM1 in TAMA on 14th. * Tube for the spot cooler was set. 4-2,3 Standard filter (Hirata) * 2 sets were finished. 5-1 Manufacturing of blade (Takahashi) * Cutting of 22 blades was finished. 5-6 Design of damper (Sato) * Original design from VIRGO does not fit to the space around BF. * The bending point is higher than the suspension point. 6-1 Design of EQ stop (Ishizaki) * Made outer shape of end plate. 6-3 Test of prototype (Ishizaki) * Assembling of the EQ stop prototype was started. * Thin dummy weights were prepared. * I-bolts on the plate were interfered with connection rods. * Outer diameter of the stop plate was larger than inner diameter of the frame lock. 6-4 Design of release sensor (Sato) * 3 sensors were attached to the plate for the prototype test. 8-1 Design of dummy payload (Okutomi, Ishizaki) * Circular type weight is suitable for combined dummy load. * Okutomi will send a cartoon soon. 9-5 Installation * Protection for falling items is necessary. Check the small bolts size to decide the mesh of net. * Discuss on evacuation of the chamber. Next meeting: 2016/7/19 13:00 = Type-A Meeting on 2016/7/5 = 2016/7/5 13:00 - 14:00 @Kamioka Participants: Takahashi, Ishizaki, Sato, Okutomi === Minutes === 0-2 Simulation (Okutomi) * The frequency shift might be due to damping model. * Matlab model was remade. * Sensors and actuators were added to the BF stage. 1-1 Clean Booth (FCL) * The booth will be ready in December. 2-1 Setting of top chamber (VAC) * The schedule was shifted to December. 2-3 Setting of cross chamber (VAC) * From 8th July, presence on 11th. 3-2 Assembly of TF+IP (Sato) * The place should be considered again. 3-5 ACC preparation (Sato) * 5 sets of ACC were measured. 5-1 Manufacturing of blade (Takahashi) * Cutting of 12 blades was finished. 5-2 Assembly of BF (Hirata) * Will be started in September. 6-3 Test of prototype (Ishizaki) * The first setup and its procedure were shown. * Thin dummy weight and short hoock should be prepared. * Some cap screws on stop plates should be replaced to stop screws. 6-4 Design of release sensor (Sato) * Under cable connection. 8-1 Design of dummy payload (Okutomi, Ishizaki) * Interferometer test was canceld. * The EQ stop and the dummy payload should be ordered together in August. 9-2 Transportation to 2F (Takahashi, Ishizaki) * Situation of the Y-end was investigated. * Maximum box width, which can go through the tunnel, was 1.5m. * Access road from Mozumi entrance was improved. 9-3 Cable assembly (Sato) * Ask CRY number of cables. Next meeting: 2016/7/12 11:00 = Type-A Meeting on 2016/6/28 = 2016/6/28 13:00 - 14:30 @The 4th meeting room Participants: Takahashi, Ishizaki, Sato, Okutomi === Minutes === 0-1 Assembly model (Ishizaki) * Made the test setup. 0-2 Simulation (Okutomi) * No progress. The results will be reported in the next VIS meeting. 1-1 Clean Booth (FCL) * Present design: The booth is hung from the ceiling. 2-3 Setting of cross chamber (VAC) * From 8th July, presence on 11th. 3-5 ACC preparation (Sato) * Working space: The 20m lab was arranged on 27th. 4-3 Standard filter (Hirata) * Assembly of FR and measurement: 1 set was finished. 5-1 Manufacturing of blade (Takahashi) * Cutting: 6 blades by July + 6 blades by Sep. 5-6 Design of damper (Sato) * Device: It is difficult to put the devices at the center of suspension point. 6-1 Design of EQ stop (Ishizaki) * Modeling: 3D model for the test setup was built. 6-3 Test of prototype * Frame lock, extension rods, adjusters were delivered. * Hoist's tool will be necessary. * Test items related to the frame design have high priority. Target date is 22th July. 6-4 Design of release sensor (Sato) * Bases and shims were delivered. * Plate additional machining: Delivery on 29th. * Circuit: LED box was made. Cabling has not been applied yet. 8-1 Design of dummy payload (Okutomi, Ishizaki) * Cartoon: Okutomi should send to Ishizaki soon! 9-1 Establishment of procedure (Takahashi, Okutomi) * Test plan is made parallel with test work. Check the list of test items. 9-2 Transportation to 2F (Takahashi, Ishizaki) * Situation of the site will be checked in 5-7th July. * Electric crawler is limitted, for example, for 200kg load. 9-3 Cable assembly (Sato) * Number of cables: CRY will decide it by the end of June. Next meeting: 2016/7/5 13:00 = Type-A Meeting on 2016/6/21 = 2016/6/21 13:00 - 14:00 by Skype Participants: Takahashi, Ishizaki, Sato === Minutes === 0-1 Assembly model (Ishizaki) * Made the test setup. 0-2 Simulation (Okutomi) * Deadline: The end of June 2-3 Setting of cross chamber (VAC) * Work: From 8th July, presence on 11th. 3-5 ACC preparation (Sato) * Make working space in the 20m lab on 27th June. 4-3 Standard filter (Hirata) * Assembly of FR and measurement: by August for 6 sets. 4-5 Procurement of magnets (Takahashi) * Size: 13mm, 72PSC for each 5-1 Manufacturing of blade (Takahashi) * Cutting: 6 blades by July + 6 blades by Sep. 5-6 Design of damper (Sato) * Device: The last one was too small, actually about 125mm. Design for vertical as well. 6-1 Design of EQ stop (Ishizaki) * Modeling: 3D model for the test setup was build. 6-3 Test of prototype * Frame lock: Delivered by 24th. * Other parts (rod, adjuster, bolts) will be ordered. 6-4 Design of release sensor (Sato) * Base: Making in ATC. * Plate additional machining: Ordered. * Circuit: LED will be tested. 8-1 Design of dummy payload (Okutomi, Ishizaki) * Cartoon: Okutomi should send to Ishizaki soon! * Mirror holder: Refer the mirror box for PR. 9-1 Establishment of procedure (Takahashi, Okutomi) * Test plan: Check FR for 2 BFs. 9-3 Cable assembly * Number of cables: Thermocouples are added. Ask Tomaru total number. Next meeting: 2016/6/28 13:00 = Type-A Meeting on 2016/6/14 = 2016/6/14 13:00 - 15:00 @ Room 210 Participants: Takahashi, Ishizaki, Sato, Okutomi === Minutes === 0-1 Assembly model (Ishizaki) * Step: From EQ stop, next with chamber. 0-2 Simulation (Okutomi) * Problem: Conversion to Simulink was ok. The structure of control has a problem in Matlab. Reconstructing now. 3-5 ACC preparation (Sato) * Space: Make working space in the 20m lab. 5-1 Manufacturing of blade (Takahashi) * Design: 5 blades are used for 200kg load. 5-6 Design of damper (Sato) * Device: Asking design of LVDT-Act. to VIRGO. The device is located at the center of mass. 6-1 Design of EQ stop (Ishizaki) * Structure analysis: Two cases were calculated. Share stress was 1/6 of limit, and principal stress was 1/7 of limit respectively in the maximum case. * Modeling: Making with consideration of procedure and tools. * Frame lock: Maximum stress was 160MPa with thickness of 30mm (limit 180MPa). 6-4 Design of release sensor (Sato) * Position: Inner side of the stage. Need to addtional machining to the EQ stop plate. * Electronics: Circuit is simple in the test (handmade). 8-1 Design of dummy payload (Okutomi, Ishizaki) * Condition: 25cm mirror, alignment by moving mass. Make a cartoon. * Actuation: Length control is necessary? Check PZT actuator. 9-1 Establishment of procedure (Takahashi, Okutomi) * Test plan: Prepare for 2 sets of release sensors. Check FR for 2 BFs. Next meeting: 2016/6/21 13:00 |

<<Navigation(children)>> |

Information of the Type-A Seismic Attenuation System (SAS). This page wants information about not only room-temperature parts but also cryogenic vibration isolation system.

Status

Contents

Drawings

- Type-A SAS whole assy

- Vacuum chamber

Vertical (IXV, EXV, IYV, EYV)

- Cryostat

Tower

- Magnetic Damper (MD)

- Bottom Filter (BF)

Cryogenic Payload

- Cryo-Payload assy

- Platform (PF)

- Marionette (MT)

- Marionette Recoil Mass

- Intermediate Mass (IM)

- Intermediate Recoil Mass

- Test Mass (TM) - Sapphire Mirror

- Recoil Mass

- Heat link

- Heat link suspension

Documents

Reports

Installation Procedure

Measurement and Analysis

- Type-A Control Simulation

- Shared with Google spread sheet (Browsing and commenting are permitted. Please contact to Okutomi for editing permission.)

- Under checking the parameters to be more realistic based on measurements and drawings

[2016.08.15] Measurements of Standard Filter

- Data of weight, optimal load, GAS resonant frequency, keystone height

- Combination of the standard filters for Type-A with ID

- X end: 3-2(F1), 2-2(F2), 1-4(F3)

- Y end: 3-3(F1), 2-1(F2), 1-3(F3)

Electronics

- General

- Quick information

- ADC accepts +/- 10 V differential =

- LVDT

- LVDT-coil combiner

- Accelerometer

- ACC driver

- Geophone

- Coil-magnet actuator

- Optical lever

- QPD board

- Stepper motor

- Stepper motor driver

- Picomotor

- Picomotor driver

- Cabling

Members of Type-A Team

- Ryutaro TAKAHASHI (Leader)

- Naohisa SATO

- Lucia TROZZO

- Yoshinori FUJII

- Koki OKUTOMI

- Hideharu ISHIZAKI

Meeting

See also

JGW-E1504005: VIS Document and Drawing Tree (Type-A)

KAGRA Dropbox > Subsystems > VIS > TypeA

| /DGSchannel /DGSrack /ETMX /ETMY /Feedthough /ITMX /ITMY /Meeting /WorkingLog /WorkingLog/dir_information |