|

Size: 2940

Comment:

|

← Revision 105 as of 2018-07-18 15:17:37 ⇥

Size: 9851

Comment:

|

| Deletions are marked like this. | Additions are marked like this. |

| Line 3: | Line 3: |

| <<MonthCalendar>> | ||<<MonthCalendar(,2018,1)>>||<<MonthCalendar(,2018,2)>>||<<MonthCalendar(,2018,3)>>||<<MonthCalendar(,2018,4)>>|| == Important note about data == * [[http://klog.icrr.u-tokyo.ac.jp/osl/?r=4612|Cryocon's misread]] == Coil Injection Time == * [[LCGT/subgroup/AOS/WideAngleBuffle/CoilInjectionTime|Coil Injection Time]] |

| Line 6: | Line 13: |

| * [[https://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=6474|Wide Angle Baffle desing review (Obuchi)]] | * [[https://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=8500|The drawings]] * [[https://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=6474|Wide Angle Baffle design review (Obuchi)]] |

| Line 9: | Line 17: |

| * [[https://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=7588|Wide Angle Baffle assembly-procedure manual (Zeidler)]] * [[https://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=4660|Calculations regarding the back-scattering of different Wide Angle Baffle designs (Zeidler)]] * [[https://nbviewer.jupyter.org/urls/dl.dropbox.com/s/niycmhy8178ed0y/WAB20170224.ipynb|Personal calc of WAB's stray light noise by Akutsu]]; due to several uncertain parameters there are several results and no one would know the actual effect! * Heat links positions (by Obuchi) [[attachment:fmkopgehpapgdkcc.png]] |

|

| Line 15: | Line 27: |

| * Place/install the WAB suspension. * Measure several relative dimensions to get useful information for the future commissioning; concretely speaking: |

* --(Place/install the WAB suspension.)-- * --(Measure several relative dimensions to get useful information for the future commissioning; concretely speaking:)-- |

| Line 18: | Line 30: |

| * Test the '''''saving mode''''' of the WAB suspension. * Don't forget to replace the damping magnets to SmCo ones; those will be delivered on '''''Jan 26'''''. |

* --(Test the '''''saving mode''''' of the WAB suspension.)-- * --(Don't forget to replace the damping magnets to SmCo ones. )-- |

| Line 21: | Line 33: |

| * Connect electric cables (with checking) in the IYC chamber. * 3 photosensors; in each photosensor head, two PDs should be connected parallel. '''''Need to calibrate the response of each sensor head...''''' * 2 heaters; should be connected parallel?? * 1 coil for actuation. * 6 thermometers with (extended?) patch cables made of phospher bronze; the extended double twisted pare cables will be delivered on '''''Jan 26''''' * Connect 4 heat links. * Check oplev signals. * Connect cables the outside as well. * Make a realtime model to monitor. * Take interface with Tcam. * Make a plan to do leak check before cooling down. |

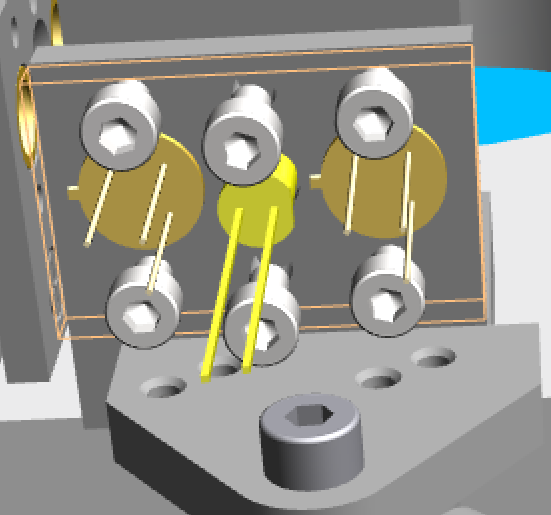

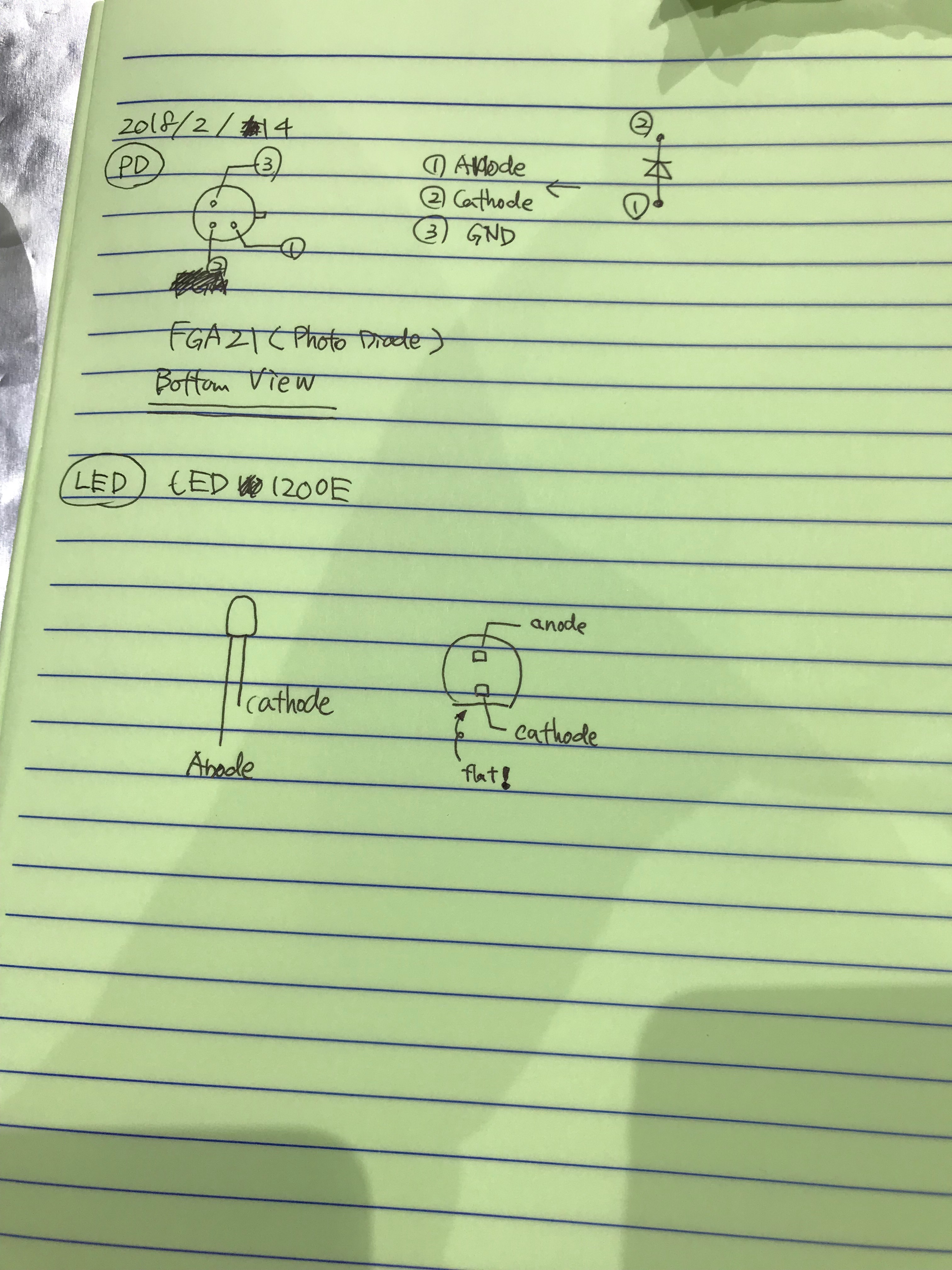

* --(Connect electric cables (with checking) in the IYC chamber.)-- * --(3 photosensors; in each photosensor head, two PDs should be connected parallel. '''''Need to calibrate the response of each sensor head...''''')-- * --(2 heaters; should be connected parallel??)-- * --(1 coil for actuation.)-- * --(6 thermometers with (extended?) patch cables made of phospher bronze; the extended double twisted pare cables will be delivered on '''''Jan 26''''')-- * --(Connect 4 heat links.)-- * --(Check oplev signals.)-- * --(Connect cables the outside as well.)-- * --(Make a realtime model to monitor.)-- * --(Take interface with Tcam.)-- * --(Make a plan to do leak check before cooling down.)-- * --(Don't forget to add some heat links (Cu?) to the top of the suspension...)-- * --(Remove the Heat-Link block)-- == Photosensor == The PDs and LED are aligned as shown in the below picture. {{attachment:PS_backside.png|Photosensor head|width="200" }} {{attachment:IMG_4151.jpg|PD and LED pin assign|width="250"}} The following LEDs and PDs are used; thanks for the information from Fukunaga-kun and Ushiba-kun. * [[https://www.thorlabs.co.jp/thorproduct.cfm?partnumber=LED1200E|LED: Thorlabs LED1200E]] * [[https://www.thorlabs.co.jp/thorproduct.cfm?partnumber=FGA21|PD: Thorlabs FGA21]] OSEM satellite amp is used to drive. * [[https://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=3499]] == Pin Assign == * Summary of the pin assign of burndy connector inside the cryostat. NOTE: The meaning of color for thermometer cable is <<BR>> RED = I- , YELLOW = I+ , GREEN = V- , BLACK = V+ P22 ||Pin Name||Resistance|| Equipment || Assign || Comment1 || Comment2 || Connection || ||A||75 ohm|| Thermometer || V- || Green || Cryocon CH A || ○ || ||B||75 ohm|| Thermometer || V+ || Black || || ○ || ||C||4 ohm|| Thermometer || I- || Red || || ○ || ||D||4 ohm|| Thermometer || I+ || Yellow || || ○ || ||E||75 ohm|| Thermometer || V- || Green || Cryocon CH B || ○ || ||F||75 ohm|| Thermometer || V+ || Black || || ○ || ||G||4 ohm|| Thermometer || I- || Red || || ○ || ||H||4 ohm|| Thermometer || I+ || Yellow || || ○ || ||J||75 ohm|| Thermometer || V- || Green || Cryocon CH C || ○ || ||K||75 ohm|| Thermometer || V+ || Black || || ○ || ||L||4 ohm|| Thermometer || I- || Red || || ○ || ||M||4 ohm|| Thermometer || I+ || Yellow || || ○ || ||N||Blank|| || || || || || ||P||75 ohm|| Thermometer || V- || Green || Cryocon CH D || ○ || ||R||75 ohm|| Thermometer || V+ || Black || || ○ || ||S||4 ohm|| Thermometer || I- || Red || || ○ || ||T||4 ohm|| Thermometer || I+ || Yellow || || ○ || ||U||75 ohm|| Thermometer || V- || Green || Cryocon CH E || ○ || ||V||75 ohm|| Thermometer || V+ || Black || || ○ || ||W||4 ohm|| Thermometer || I- || Red || || ○ || ||X||4 ohm|| Thermometer || I+ || Yellow || || ○ || ||Y||Blank|| || || || || || P23 ||Pin Name||Resistance|| Equipment || Assign || Comment1 || Comment2 || Connection || ||A||75 ohm|| Thermometer || V- || Green || Cryocon CH F || ○ || ||B||75 ohm|| Thermometer || V+ || Black || || ○ || ||C||4 ohm|| Coil Mag. Act. || I- || || ''As low resistor line was needed.'' || ○ || ||D||4 ohm|| Coil Mag. Act. || I+ || || ''As low resistor line was needed.'' || ○ || ||E||75 ohm|| PS1 PD || V- (K)|| || || ○ || ||F||75 ohm|| PS1 PD || V+ (A)|| || || ○ || ||G||4 ohm|| PS1 LED || I- (K)|| || || ○ || ||H||4 ohm|| PS1 LED || I+ (A)|| || || ○ || ||J||75 ohm|| PS2 PD || V- (K)|| || || ○ || ||K||75 ohm|| PS2 PD || V+ (A)|| || || ○ || ||L||4 ohm|| PS2 LED || I- (K)|| || || ○ || ||M||4 ohm|| PS2 LED || I+ (A)|| || || ○ || ||N||Blank|| || || || || || ||P||75 ohm|| PS3 PD || V- (K)|| || || ○ || ||R||75 ohm|| PS3 PD || V+ (A)|| || || ○ || ||S||4 ohm|| PS3 LED || I- (K)|| || || ○ || ||T||4 ohm|| PS3 LED || I+ (A)|| || || ○ || ||U||75 ohm|| Thermometer || I- || Red|| Cryocon CH F || ○ || ||V||75 ohm|| Thermometer || I+ || Yellow || Cryocon CH F || ○ || ||W||4 ohm|| Heater || I- || || || ○ || ||X||4 ohm|| Heater || I+ || || || ○ || ||Y||Blank|| || || || || || {{attachment:burndy_cryostat.png | Diagram|width="300" }} |

| Line 81: | Line 167: |

== OpLev == * Optical lever installed at the +X/-Y side of the IYC * Path-length inside the chamber (viewport to viewport): ~3000 mm {{attachment:ETMchamber_WAB_oplev_beams3.PNG| Diagram|width="500"}} == WAB Alignment == * Alignment done with 2 laser-leveler inside the IYC * Regarding the used terms: * As the baffle is placed along the Y-arm, +Y and -Y refer to both long ends of the baffle toward the Y-end and toward the center area, respectively! * The same holds true for the horizontal dimension in x-arm direction (+X means toward X-end and -X toward center/PSL) === Yaw === * laser-leveler needs to be close to the -Y main-beam entrance in a height 300 - 400 mm above the optical table * Vertical laser line to be adjusted to the main-beam indication on the optical table and the inner wall of the cryostat * Checked the line by using the slids of the flanges on top the WAB (each slid is ~3.5 mm broad) * For both slids, the laser line is mismatched (not centered) toward -X by ~0.5 mm (@ +Y slid) and ~1 mm (@ -Y slid) That means that there is probably also a -X offset! * The flanges have a distance of 170 mm which indicates a maximum yaw-tilting of ~0.1 degrees '''Note:''' taking the distances is very hard as the position of the slids is not easy to access === Pitch === * laser-leveler outside the cryostat (but inside IYC) set to give a horizontal line along length side of the baffle * Found a slight mismatch for the outer screw holding the OpLev mirrors in +Y,+X and -Y,+X * Difference is ~1 mm (+Z @ -Y, so -Y-side is higher than +Y-side) * With approx. 500 mm distance between both screws, the maximum pitch is ~0.1 degrees === Roll === * Took the height of the OpLev mirror screw-holes (@ -Y,+X and -Y,-X) with a vertical ruler and the horizontal line of the laser-leveler outside the cryostat * Measured a difference of 2.5 mm which makes it a roll of 0.55 degrees (radius of baffle ~130 mm); -Y,-X is higher! * Then took the height of baffle-wings which are mounted on the flanges and could not measure any difference (within an error of 0.5 mm) * Hence, only the baffle is slightly rolled within the flanges! |

Wide Angle Baffle Cooling Test 2018

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Important note about data

Coil Injection Time

Links to knowledge

Calculations regarding the back-scattering of different Wide Angle Baffle designs (Zeidler)

Personal calc of WAB's stray light noise by Akutsu; due to several uncertain parameters there are several results and no one would know the actual effect!

Heat links positions (by Obuchi) fmkopgehpapgdkcc.png

Task list

Note: some of the tasks can be done in parallel.

Place/install the WAB suspension.

Measure several relative dimensions to get useful information for the future commissioning; concretely speaking:

- What....?

Test the saving mode of the WAB suspension.

Don't forget to replace the damping magnets to SmCo ones.

- What is the requirement to say the damping is sufficient...?

Connect electric cables (with checking) in the IYC chamber.

3 photosensors; in each photosensor head, two PDs should be connected parallel. Need to calibrate the response of each sensor head...

2 heaters; should be connected parallel??

1 coil for actuation.

6 thermometers with (extended?) patch cables made of phospher bronze; the extended double twisted pare cables will be delivered on Jan 26

Connect 4 heat links.

Check oplev signals.

Connect cables the outside as well.

Make a realtime model to monitor.

Take interface with Tcam.

Make a plan to do leak check before cooling down.

Don't forget to add some heat links (Cu?) to the top of the suspension...

Remove the Heat-Link block

Photosensor

The PDs and LED are aligned as shown in the below picture.

The following LEDs and PDs are used; thanks for the information from Fukunaga-kun and Ushiba-kun.

OSEM satellite amp is used to drive.

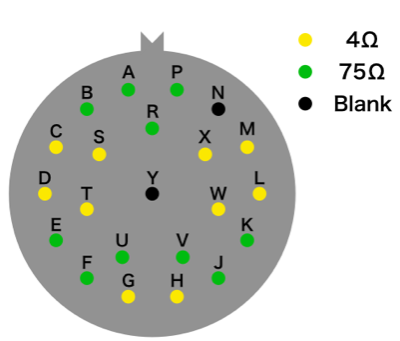

Pin Assign

- Summary of the pin assign of burndy connector inside the cryostat.

NOTE: The meaning of color for thermometer cable is

RED = I- , YELLOW = I+ , GREEN = V- , BLACK = V+

P22

Pin Name |

Resistance |

Equipment |

Assign |

Comment1 |

Comment2 |

Connection |

A |

75 ohm |

Thermometer |

V- |

Green |

Cryocon CH A |

○ |

B |

75 ohm |

Thermometer |

V+ |

Black |

|

○ |

C |

4 ohm |

Thermometer |

I- |

Red |

|

○ |

D |

4 ohm |

Thermometer |

I+ |

Yellow |

|

○ |

E |

75 ohm |

Thermometer |

V- |

Green |

Cryocon CH B |

○ |

F |

75 ohm |

Thermometer |

V+ |

Black |

|

○ |

G |

4 ohm |

Thermometer |

I- |

Red |

|

○ |

H |

4 ohm |

Thermometer |

I+ |

Yellow |

|

○ |

J |

75 ohm |

Thermometer |

V- |

Green |

Cryocon CH C |

○ |

K |

75 ohm |

Thermometer |

V+ |

Black |

|

○ |

L |

4 ohm |

Thermometer |

I- |

Red |

|

○ |

M |

4 ohm |

Thermometer |

I+ |

Yellow |

|

○ |

N |

Blank |

|

|

|

|

|

P |

75 ohm |

Thermometer |

V- |

Green |

Cryocon CH D |

○ |

R |

75 ohm |

Thermometer |

V+ |

Black |

|

○ |

S |

4 ohm |

Thermometer |

I- |

Red |

|

○ |

T |

4 ohm |

Thermometer |

I+ |

Yellow |

|

○ |

U |

75 ohm |

Thermometer |

V- |

Green |

Cryocon CH E |

○ |

V |

75 ohm |

Thermometer |

V+ |

Black |

|

○ |

W |

4 ohm |

Thermometer |

I- |

Red |

|

○ |

X |

4 ohm |

Thermometer |

I+ |

Yellow |

|

○ |

Y |

Blank |

|

|

|

|

|

P23

Pin Name |

Resistance |

Equipment |

Assign |

Comment1 |

Comment2 |

Connection |

A |

75 ohm |

Thermometer |

V- |

Green |

Cryocon CH F |

○ |

B |

75 ohm |

Thermometer |

V+ |

Black |

|

○ |

C |

4 ohm |

Coil Mag. Act. |

I- |

|

As low resistor line was needed. |

○ |

D |

4 ohm |

Coil Mag. Act. |

I+ |

|

As low resistor line was needed. |

○ |

E |

75 ohm |

PS1 PD |

V- (K) |

|

|

○ |

F |

75 ohm |

PS1 PD |

V+ (A) |

|

|

○ |

G |

4 ohm |

PS1 LED |

I- (K) |

|

|

○ |

H |

4 ohm |

PS1 LED |

I+ (A) |

|

|

○ |

J |

75 ohm |

PS2 PD |

V- (K) |

|

|

○ |

K |

75 ohm |

PS2 PD |

V+ (A) |

|

|

○ |

L |

4 ohm |

PS2 LED |

I- (K) |

|

|

○ |

M |

4 ohm |

PS2 LED |

I+ (A) |

|

|

○ |

N |

Blank |

|

|

|

|

|

P |

75 ohm |

PS3 PD |

V- (K) |

|

|

○ |

R |

75 ohm |

PS3 PD |

V+ (A) |

|

|

○ |

S |

4 ohm |

PS3 LED |

I- (K) |

|

|

○ |

T |

4 ohm |

PS3 LED |

I+ (A) |

|

|

○ |

U |

75 ohm |

Thermometer |

I- |

Red |

Cryocon CH F |

○ |

V |

75 ohm |

Thermometer |

I+ |

Yellow |

Cryocon CH F |

○ |

W |

4 ohm |

Heater |

I- |

|

|

○ |

X |

4 ohm |

Heater |

I+ |

|

|

○ |

Y |

Blank |

|

|

|

|

|

DAQ

Real-time computer: k1???

Slot |

Item |

Assigned to |

S/N |

42 |

<blank> |

|

|

41 |

<blank> |

|

|

40 |

<blank> |

|

|

39 |

<blank> |

|

|

38 |

<blank> |

|

|

37 |

<blank> |

|

|

36 |

<blank> |

|

|

35 |

<blank> |

|

|

34 |

<blank> |

|

|

33 |

<blank> |

|

|

32 |

<blank> |

|

|

31 |

<blank> |

|

|

30 |

<blank> |

|

|

29 |

<blank> |

|

|

28 |

<blank> |

|

|

27 |

<blank> |

|

|

26 |

<blank> |

|

|

25 |

<blank> |

|

|

24 |

<blank> |

|

|

23 |

<blank> |

|

|

22 |

<blank> |

|

|

21 |

<blank> |

|

|

20 |

<blank> |

|

|

19 |

<blank> |

|

|

18 |

<blank> |

|

|

17 |

<blank> |

|

|

16 |

<blank> |

|

|

15 |

<blank> |

|

|

14 |

<blank> |

|

|

13 |

<blank> |

|

|

12 |

AI Chassis |

DAC0 |

SN??? |

11 |

AA Chassis |

ADC0 |

SN??? |

10 |

<blank> |

|

|

9 |

I/O Chassis |

|

SN??? |

8 |

<blank> |

|

|

7 |

<blank> |

|

|

6 |

<blank> |

|

|

5 |

<blank> |

|

|

4 |

<blank> |

|

|

3 |

<blank> |

|

|

2 |

<blank> |

|

|

1 |

<blank> |

|

|

0 |

<blank> |

|

|

OpLev

- Optical lever installed at the +X/-Y side of the IYC

- Path-length inside the chamber (viewport to viewport): ~3000 mm

WAB Alignment

- Alignment done with 2 laser-leveler inside the IYC

- Regarding the used terms:

- As the baffle is placed along the Y-arm, +Y and -Y refer to both long ends of the baffle toward the Y-end and toward the center area, respectively!

- The same holds true for the horizontal dimension in x-arm direction (+X means toward X-end and -X toward center/PSL)

Yaw

- laser-leveler needs to be close to the -Y main-beam entrance in a height 300 - 400 mm above the optical table

- Vertical laser line to be adjusted to the main-beam indication on the optical table and the inner wall of the cryostat

- Checked the line by using the slids of the flanges on top the WAB (each slid is ~3.5 mm broad)

- For both slids, the laser line is mismatched (not centered) toward -X by ~0.5 mm (@ +Y slid) and ~1 mm (@ -Y slid)

That means that there is probably also a -X offset!

- The flanges have a distance of 170 mm which indicates a maximum yaw-tilting of ~0.1 degrees

Note: taking the distances is very hard as the position of the slids is not easy to access

Pitch

- laser-leveler outside the cryostat (but inside IYC) set to give a horizontal line along length side of the baffle

Found a slight mismatch for the outer screw holding the OpLev mirrors in +Y,+X and -Y,+X

- Difference is ~1 mm (+Z @ -Y, so -Y-side is higher than +Y-side)

- With approx. 500 mm distance between both screws, the maximum pitch is ~0.1 degrees

Roll

Took the height of the OpLev mirror screw-holes (@ -Y,+X and -Y,-X) with a vertical ruler and the horizontal line of the laser-leveler outside the cryostat

- Measured a difference of 2.5 mm which makes it a roll of 0.55 degrees (radius of baffle ~130 mm); -Y,-X is higher!

- Then took the height of baffle-wings which are mounted on the flanges and could not measure any difference (within an error of 0.5 mm)

- Hence, only the baffle is slightly rolled within the flanges!